These Smart Bolts Change Color When You Tighten Them Properly

Tightening bolts is simple enough until you accidentally do it wrong. Over-tighten them, and you end up stripping screws, snapping screw heads, or damaging the threading that holds the bolts in place, allowing them to slowly vibrate out over time. Screw them on too loosely, and they might sustain stress that causes them to snap or work their way right out of their joints. Even slightly under-tightened bolts tend to loosen more and more over time in a way that’s not easy to catch until it’s too late.

Lucky for us all, a company called Stress Indicators Inc. is now offering one of those “why didn’t this already exist” products in the form of SmartBolts, completely eliminating the need for a torque wrench to ensure that bolts are properly fastened. Each one of these bolts boasts a red dot in the center of its head that disappears when you’ve tightened it just right, which means you’ll always know when you’ve hit the sweet spot. You’ll also get visual cues when you need to re-tighten bolts that have loosened over time.

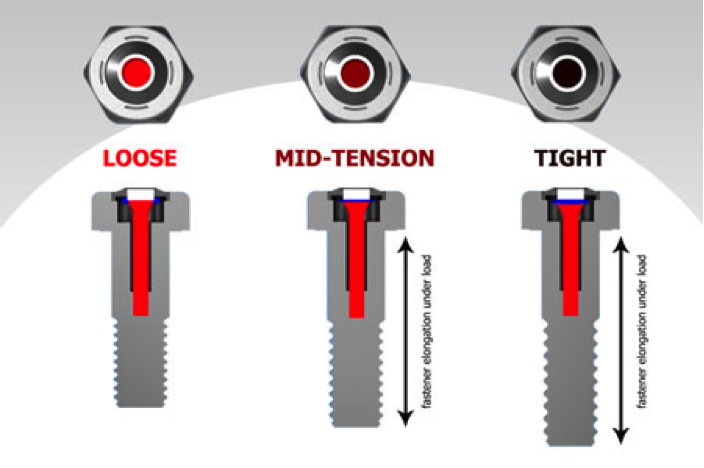

Fasteners work like springs, the company explains. Every time you stretch a spring, it pulls back. That stretching force is known as tension, while the force that attempts to return the spring to its original size is called compression. And since tension creates a kind of clamp force, it’s perfect for holding objects together.

The SmartBolt’s built-in visual tension indicator shows you exactly how much tension is being applied to the screw, appearing bright red when it’s at its loosest and darkening several shades until it reaches the black color that indicates it’s properly tightened.

“Even though bolts may seem perfectly rigid, steel is an elastic material. This means that when they are tightened in a bolted joint, they actually stretch a tiny amount. Think of the bolt in a bolted joint as a stiff, metal spring. By tightening the nut, you are creating tension, a load or force that pulls on both ends of the bolt. As you increase the tension, the bolt stretches the way a spring would stretch when you pull against both ends.”

“From loose to tight and back again, the system is reliable and repeatable through countless cycles of operation. It is compatible with a wide range of fastener types, and we can adapt it to fasteners of nearly every available grade, finish, and coating.”

SmartBolts are available in a range of sizes, going all the way up to 2.2 inches in diameter for industrial usage in fields like mining. In fact, the largest ones weigh a whopping 25 pounds each. While they might be overkill for some applications, it’s clear that bolts with built-in visual indicators could offer a major safety boost for things like infrastructure and, say, roller coasters.

Perhaps in the latter case, if products like SmartBolts became the norm, people with anxieties about equipment failure could reassure themselves that they’d be fine to go on certain rides with just a quick visual assessment.

Where else do you imagine bolts like these coming in handy?