Dyson Designed a New Ventilator for Coronavirus Patients in Just 10 Days

All over the world, companies are rapidly shifting their production lines and business models to address shortages of critical equipment needed to fight the spread of COVID-19. Just like small producers of outdoor furniture had no idea they’d be sewing face masks for healthcare workers, vacuum maker Dyson probably wouldn’t have pegged ventilators for their next big project. Yet, at the request of British Prime Minister Boris Johnson, company founder James Dyson has designed a new ventilator in just ten days, and his company will be making at least 15,000 of them in the coming weeks.

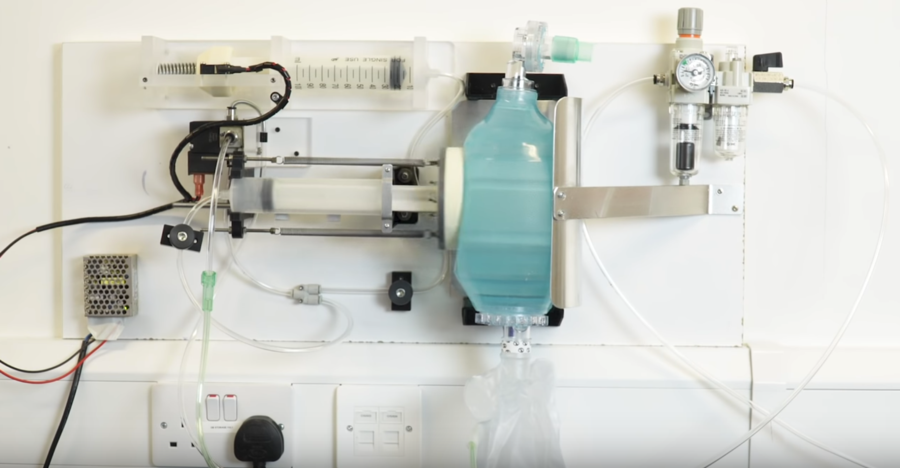

The “CoVent” was designed for lifesaving use on COVID-19 patients. Like other ventilator designs, it’s made to push air and increased levels of oxygen into the lungs. One in five people infected with the disease becomes seriously ill and in need of hospital care, and five percent of patients develop critical respiratory distress requiring invasive breathing support. Tens of thousands of new ventilators are needed around the world as demand dramatically overwhelms supply.

Teaming up with The Technology Partnership, a medical devices company based in Cambridge, Dyson used its digital motor technology and air movement expertise to design the CoVent and manufacture it as rapidly as possible. The company, best known for its vacuums, hair dryers, and air purifiers, doesn’t expect to make a profit from the venture.

“This new device can be manufactured quickly, efficiently, and at volume,” founder Sir James Dyson wrote in an email to his staff obtained by the Financial Times. “It is designed to a dress the specific clinical needs of COVID-19 patients, and it is suited to a variety of clinical settings. The core challenge was how to design and deliver a new, sophisticated medical product in volume and in an extremely short space of time. The race is now on to get it into production.”

The CoVent ventilators will be assembled at Dyson’s research center in Hullavington, Wiltshire, located on the site of a former Royal Air Force base, and will contain motors made in Singapore, where the company recently scrapped an electric car program. It meets clinician specifications for ventilator hardware and can be either bed-mounted or portable, with a battery power supply for flexible use during patient transport and in field hospitals.

Since it only slightly modifies Dyson’s existing Digital Motor design, the fan units needed to produce it are “available in very high volume.” 10,000 units will go to the United Kingdom, and the other 5,000 will be donated to the international effort to fight the novel coronavirus.

In Britain alone, the National Health Service has access to just 8,175 ventilators at a time when a staggering 60,000 are needed. UK-based manufacturers don’t typically produce this type of equipment, either, requiring producers of automotive, aerospace, and engineering products to think creatively. Other suppliers have submitted proof of concepts to the government as well, but the machines must pass regulatory tests before they’re used.

Gtech, another UK-based home appliance and vacuum manufacturer, will also be producing up to 30,000 ventilators in a two-week span using parts easily obtained from its own stock materials. The company plans to produce about 100 per day within a week, assuming it can source enough steel fabrication and CNC machining suppliers. Gtech will also be making its designs available for free to the public so other companies can quickly get on board and start using their own manufacturing capabilities to help.