Researchers Develop 4D-Printed Bio-Ink for Organ and Tissue Regeneration

Researchers at the University of Chicago recently invented a 4D-printed living material that could be a game-changer for organ and tissue regeneration.

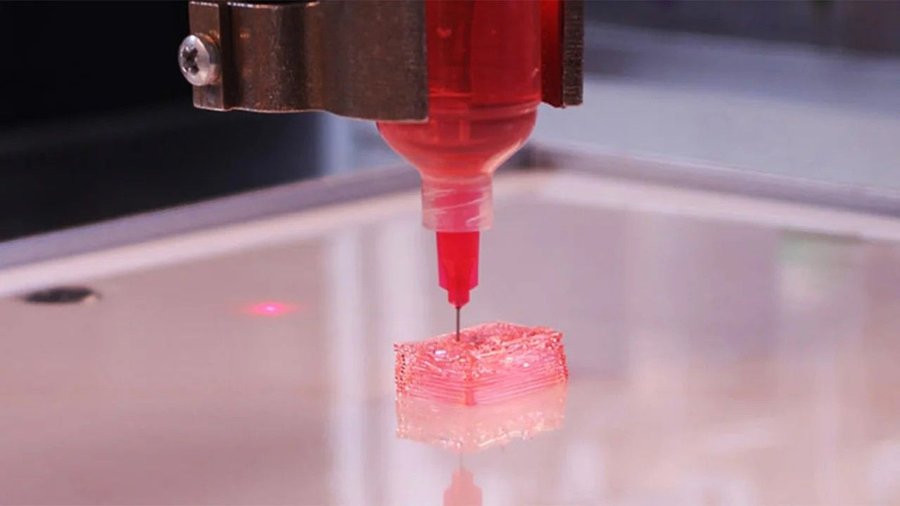

Most people have heard of 3D printing — a manufacturing process that involves pushing a building material like plastic or resin through a machine that forms it into a precise and predetermined shape. This type of printing is revolutionizing all kinds of industries from construction to automobiles. Scientists have also been able to 3D print tissues and biological parts from living cells called bio-inks.

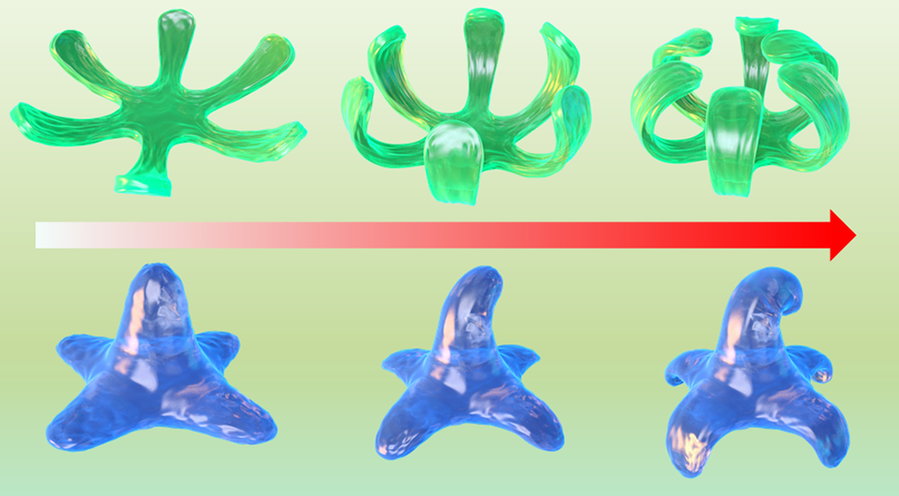

The University of Chicago engineers have taken that process one step further by developing a bio-ink that can be printed in four dimensions. That means there’s also a time component to the product. Namely, this special bio-ink can instruct the material to transform its shape over time. It can even do this multiple times in a preprogrammed schedule or on-demand in response to external signals.

“This bio-ink system provides the opportunity to print bio-constructs capable of achieving more sophisticated architectural changes over time than was previously possible,” says research leader Eben Alsberg, a professor in the departments of biomedical, mechanical, and industrial engineering, pharmacology and regenerative medicine, and orthopedics in a university publication.

“These cell-rich structures with pre-programmable and controllable shape morphing promise to better mimic the body’s natural developmental processes and could help scientists conduct more accurate studies of tissue morphogenesis and achieve greater advances in tissue engineering,” he adds.

The bio-ink Alsberg and his team created is made up of tightly-packed, flake-shaped microgels and living cells.

“The bio-inks have what are called shear-thinning and rapid self-healing properties that enable smooth extrusion-based printing with high resolution and high fidelity without a supporting bath. The printed bioconstructs, after further stabilization by light-based crosslinking, remain intact while, for example, bending, twisting, or undergoing any number of multiple deformations. With this system, cartilage-like tissues with complex shapes that evolve over time could be bioengineered,” Alsberg explains.

The team published their work in the science periodical Advanced Materials in a study titled “Jammed Micro-Flake Hydrogel for Four-Dimensional Living Cell Bioprinting,” sharing the results of their experiments with the prototype hydrogels.

“This is the first system that meets the demanding requirements of bioprinting 4D constructs: load living cells in bio-inks, enable printing of large complex structures, trigger shape transformation under physiological conditions, support long-term cell viability, and facilitate desired cell functions such as tissue regeneration,” says Aixiang Ding, Team Member and Postdoctoral Research Associate at UIC.

This groundbreaking, shape-shifting bio-ink could make it possible to 4D-print livers, kidneys, and perhaps even hearts that can better copy the shape, function, and healing properties of natural organs.

“We are endeavoring to translate this system into clinical applications of tissue engineering, as there is a critical shortage of available donor tissues and organs,” Ding adds.

If this new bio-ink can live up to its potential, it could drastically reduce and eventually eliminate the need for human organ donors, potentially saving thousands of lives of those on transplant waiting lists each year.