Regenerative High-Rise: Modular Timber Tower Design Can Be Adapted for Any City

Not so long ago, it was exceptionally rare to see timber buildings more than six stories tall. But new engineered wood technologies like cross-laminated timber (CLT), glued laminated wood (gluluam), and laminated veneer lumber (LVL) have revolutionized wooden architecture, making it possible to build timber high-rises that are just as strong as conventional buildings made from steel and concrete. Architecture and engineering firms Haptic and Ramboll now expand on these capabilities with a wooden high-rise that’s also modular for maximum flexibility and longevity.

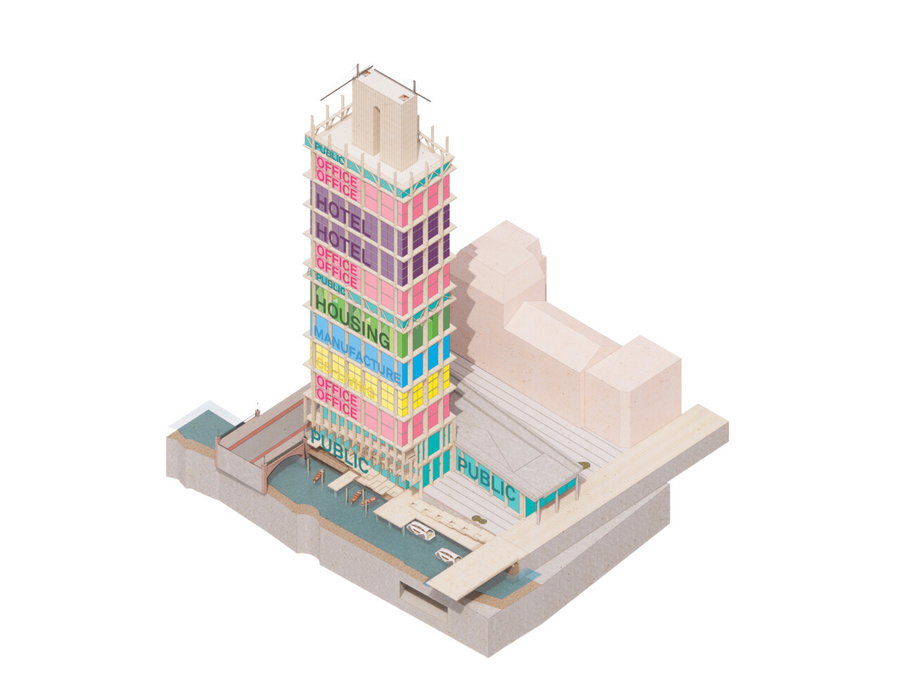

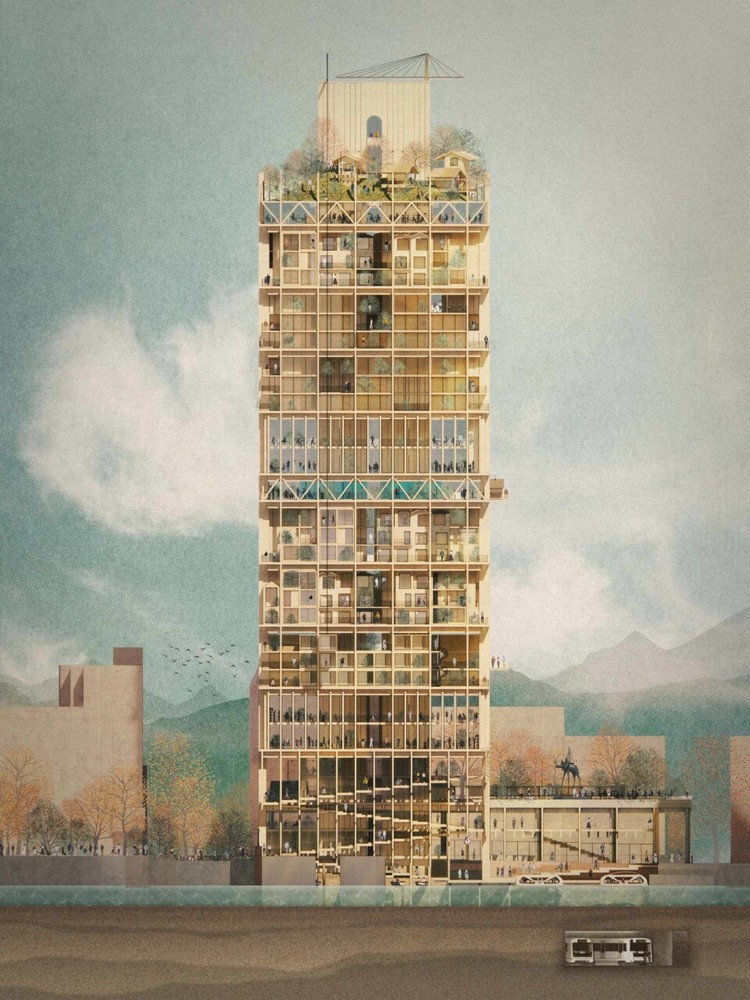

Built in a densely populated urban area in the middle of Oslo, Norway, the Regenerative High-Rise features a main structural frame consisting of three-story-high decks that can each support either three intermediate floor plates or three levels of versatile, varying-height pods. According to the architects, this design makes the system adaptable both horizontally and vertically. Single, double, or triple-height partitions can be inserted within each level to allow for interior layouts suited to residential, office, hotel leisure, or production uses.

The idea is that the building can be continually modified over time to suit new uses that may come up in the future. The difficulty of retrofitting old buildings is currently a major challenge for developers in cities around the world, especially in high-rises designed for a particular function, like offices or apartments. Haptic and Ramboll’s “triple-height sky villages,” as they call them, aim to bring the sense of community traditionally found in Olso’s suburbs to its urban core through mixed-use buildings that can change along with the neighborhood and the times.

The first fully realized Regenerative High-Rise even makes use of an interesting pre-existing feature onsite, incorporating a disused motor viaduct into its foundations to demonstrate how road infrastructure can be creatively repurposed.

“The natural materials bring warmth to the high-rise while also contributing to the life cycle carbon management of the development,” say the architects. “The building core has a maintenance unit at the top capable of lifting the pods and intermediate floors. This function is expected to be used during the whole life span of the building, not just during its construction. The pods also are designed to be moved and reused throughout the building to allow it to be reprogrammed over time, depending on the needs of the city.”

“The most exciting component of the Regenerative Tower is the idea of vertical land creation,” says Shonn Mills, Global Director of Ramboll High Rise. “With the tower, we are essentially producing volumes that can flex and change in use and character with the needs and requirements of the city. This makes sure the building stays competitive and relevant far longer than the normal building life cycle, which also makes it more sustainable.”

If you see high-rise timber projects like this as giant tinder boxes waiting to ignite, you might be interested to learn that recent research shows materials like glulam, CLT, and LVL are surprisingly resilient in a fire. The charring of wood creates an insulating layer that protects the inner part of the timber, leaving cross-sections of undamaged wood capable of carrying heavy loads after the fire is out. Steel, on the other hand, melts at high temperatures, and concrete collapses without its reinforcement. Produced with extreme precision, engineered wood components are also easy to assemble, and they come from a renewable source.